Holding electromagnets

Top selling products in the category

There are 47 products.

Electromagnet 10kg, 100N, 20x25mm, demagnetizing

In stock

Fully encapsulated industrial grade degaussing electromagnet with 100N holding force. The electromagnet after connecting the el. energy demagnetizes.

10.84 €

21.68 €

10.84 € without VAT

Electromagnet 70kg, 700N, 80x40x30mm

In stock

Fully encapsulated industrial grade rectangular electromagnet with 700N holding force.

108.06 €

108.06 € without VAT

Electromagnet 1kg, 10N, 15x5mm

In stock

Fully encapsulated industrial grade electromagnet with 10N holding force.

17.68 €

17.68 € without VAT

Electromagnet 8kg, 80N, 38x8mm

In stock

Fully encapsulated industrial grade electromagnet with 80N holding force.

14.04 €

14.04 € without VAT

Electromagnet 200kg, 2000N, 80x80mm

In stock at supplier

Fully encapsulated industrial grade electromagnet with 2000N holding force.

150.01 €

150.01 € without VAT

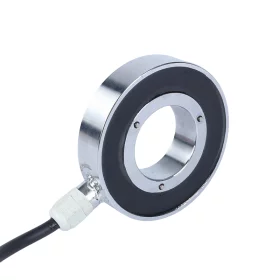

Circular electromagnet 50kg, 500N, D80x20mm

In stock

Fully encapsulated industrial grade electromagnet with 100N holding force.

114.46 €

114.46 € without VAT

Electromagnet 1kg, 10N, 12x12mm, demagnetizing

In stock

Fully encapsulated industrial grade degaussing electromagnet with 10N holding force. Electromagnet after connecting el. energy demagnetizes.

18.78 €

18.78 € without VAT

Electromagnet 30kg, 300N, 50x30x20mm

In stock

Fully encapsulated industrial grade rectangular electromagnet with 1000N holding force.

58.64 €

58.64 € without VAT

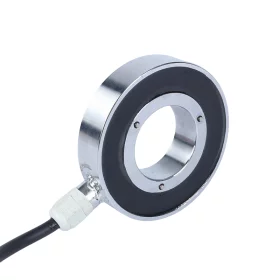

Circular electromagnet 100kg, 1000N, D90x20mm

In stock

Fully encapsulated industrial grade electromagnet with 100N holding force.

118.83 €

118.83 € without VAT

Electromagnet 2.5kg, 25N, 15x15mm, demagnetizing

In stock

Fully encapsulated demagnetising electromagnet in industrial quality with a holding force of 25 N. The electromagnet demagnetises after connection of electric power.

18.78 €

18.78 € without VAT

Electromagnet 5kg, 50N, 25x20mm

In stock

Fully encapsulated industrial quality electromagnet with 50N holding force.

5.77 €

5.77 € without VAT

Electromagnet 20kg, 200N, 40x25mm, demagnetizing

In stock

Fully encapsulated demagnetizing electromagnet in industrial quality with a holding force of 200 N. The electromagnet demagnetizes after connection of electric power .

39.89 €

39.89 € without VAT

Electromagnet 1kg, 10N, 13x27mm

In stock

Fully encapsulated industrial quality electromagnet with 10N holding force.

6.94 €

6.94 € without VAT

Electromagnet 10kg, 100N, 25x29mm, demagnetizing

In stock at supplier

Fully encapsulated industrial quality pernament electromagnet with a holding force of 100 N. The electromagnet demagnetizes after connecting electrical power.

30.08 €

30.08 € without VAT

Electromagnet 40kg, 400N, 40x29mm, demagnetizing

In stock at supplier

Fully encapsulated demagnetising electromagnet in industrial quality with a holding force of 400 N. The electromagnet demagnetises after connection of electric power.

59.73 €

59.73 € without VAT

Electromagnet 30kg, 300N, 35x29mm, demagnetizing

In stock

Fully encapsulated demagnetizing electromagnet in industrial quality with a holding force of 300 N. The electromagnet demagnetizes after connection of electric power.

50.46 €

50.46 € without VAT

Electromagnet 50kg, 500N, 50x30mm, demagnetizing

In stock

Fully encapsulated demagnetizing electromagnet in industrial quality with a holding force of 500 N. The electromagnet demagnetizes after connection of electric power.

67.37 €

67.37 € without VAT

Electromagnet 60kg, 600N, 50x35mm, demagnetizing

In stock

Fully encapsulated demagnetizing electromagnet in industrial quality with a holding force of 600 N. The electromagnet demagnetizes after connection of electric power.

67.80 €

67.80 € without VAT

Electromagnet 66kg, 660N, 63x29mm, demagnetizing

Last items in stock

Fully encapsulated demagnetizing electromagnet in industrial quality with a holding force of 660 N. The electromagnet demagnetizes after connection of electric power.

127.30 €

127.30 € without VAT

Electromagnet 92kg, 920N, 70x45mm, demagnetizing

In stock at supplier

Fully encapsulated demagnetising electromagnet in industrial quality with a holding force of 920 N. The electromagnet demagnetises after connection of electric power.

143.68 €

143.68 € without VAT